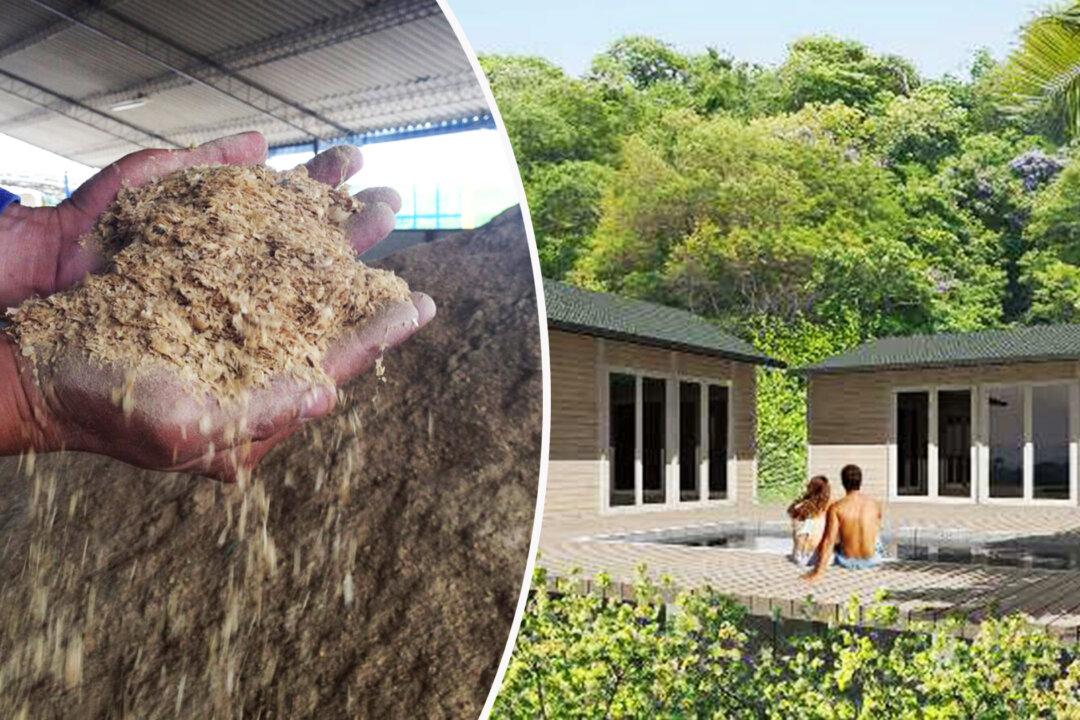

More and more, home builders are looking into eco-friendly alternatives to the standard way of building homes. One new type of home in Colombia is being made from an unlikely and Earth-friendly building material: coffee.

But this doesn’t mean perfectly good coffee beans are going to waste; these homes incorporate coffee husks, a disposable byproduct of the bean, in their building materials.