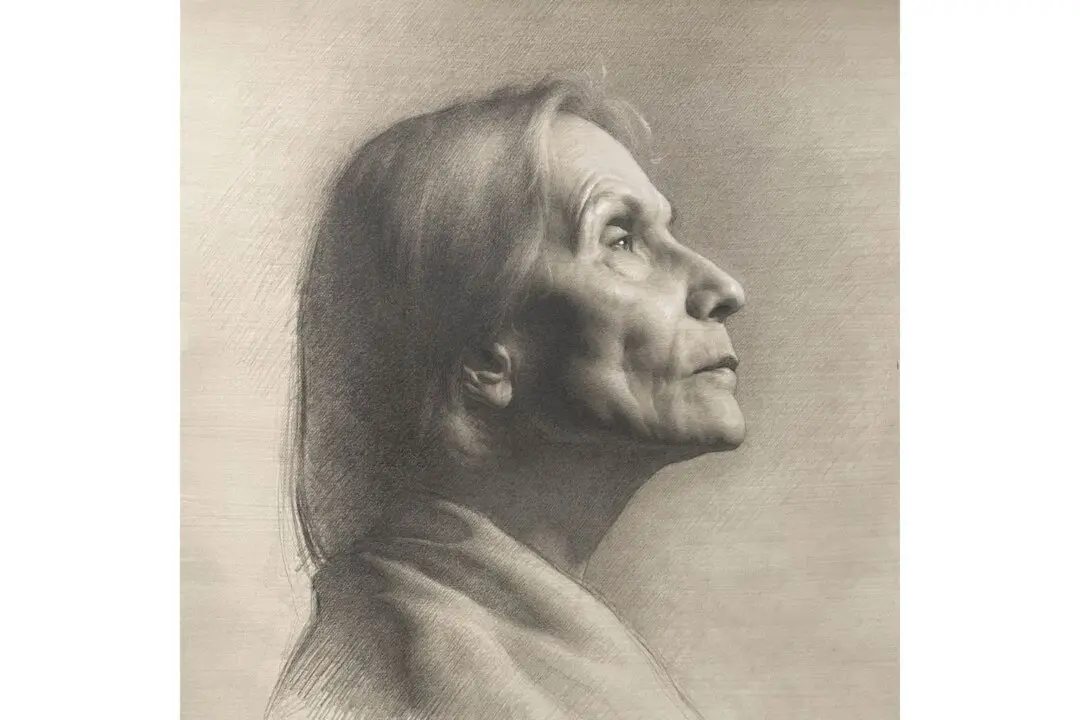

Felicity Irons is one of the last rush matters working in the UK and runs the only business that does the whole process from harvest to home product, she says. In 2017, she was awarded a British Empire Medal, a national honor, for her work.

Not only has Irons created a sustainable local business based on the traditional craft of harvesting and plaiting bulrush by hand, but she’s reinvigorated a craft that had nearly disappeared if it were not for a fateful meeting on a rural riverbank.