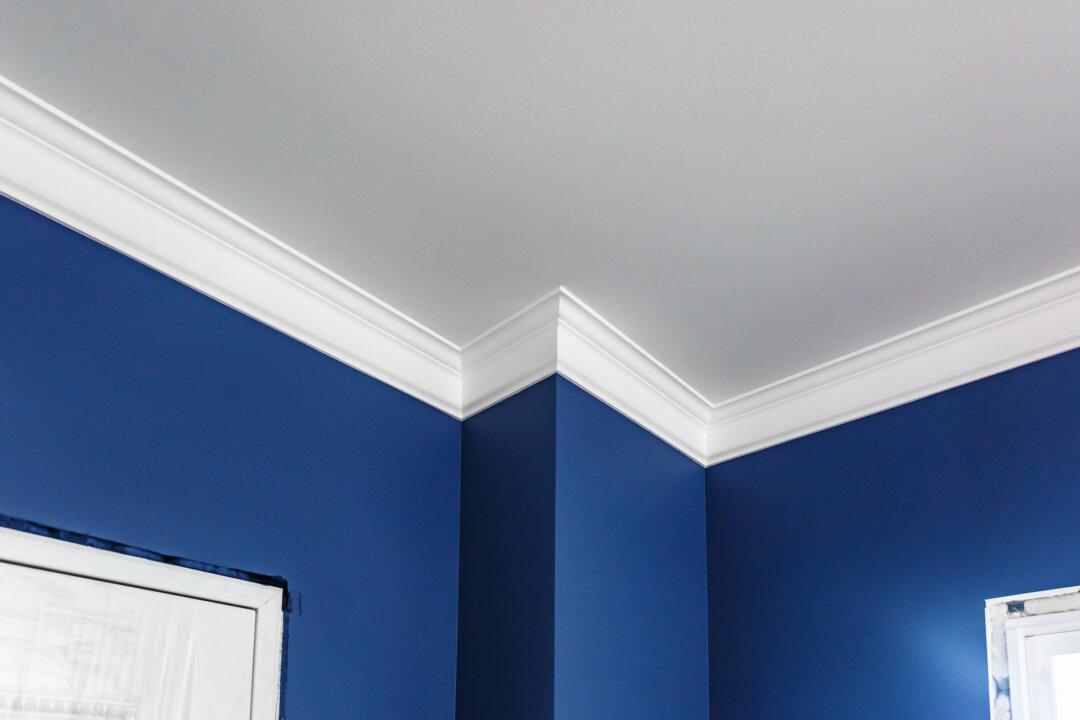

Dear James: I like the look of crown molding for my dining room, but I am having trouble getting the corner cut for a good fit. Is there a proper way to cut them?—Jessica P.

Dear Jessica: Fitting the corners for crown molding is a challenge even for experienced remodelers and builders. They will fill the gaps in the corners with wood filler and sand them smooth. Over time, the filler dries out, and with humidity level changes, the corners look bad.