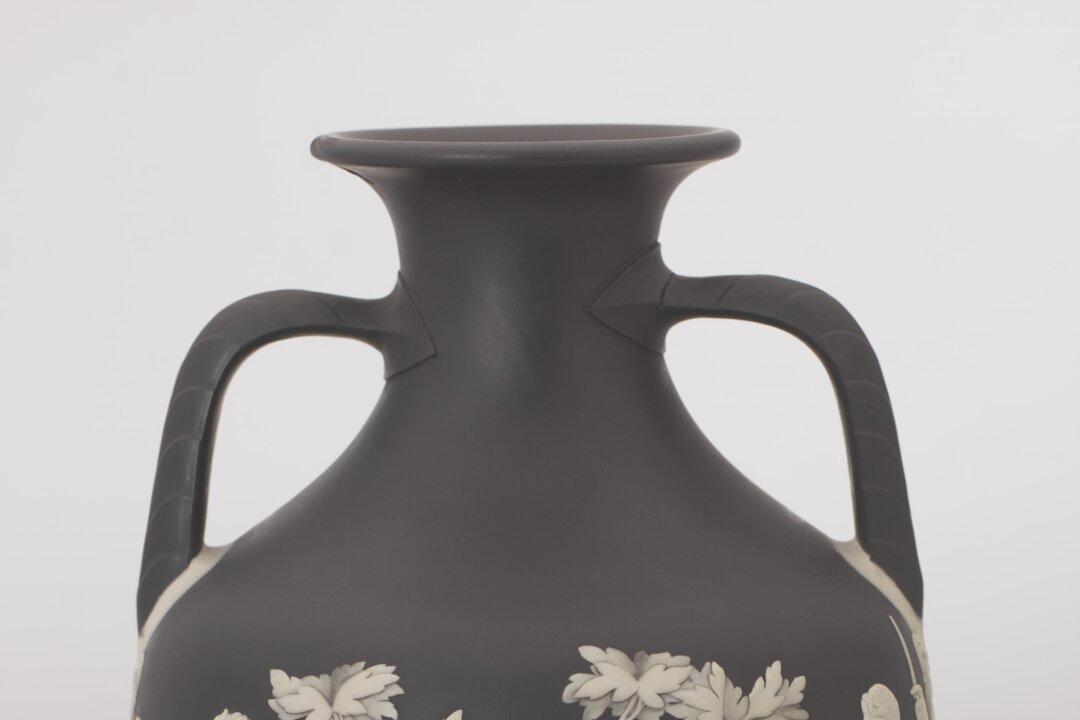

Josiah Wedgwood spent his life perfecting the art of pottery, establishing 260 years ago the company that bears his family name. His near-perfect works were and still are the choice for monarchs, heads of state, and purveyors of good taste worldwide.

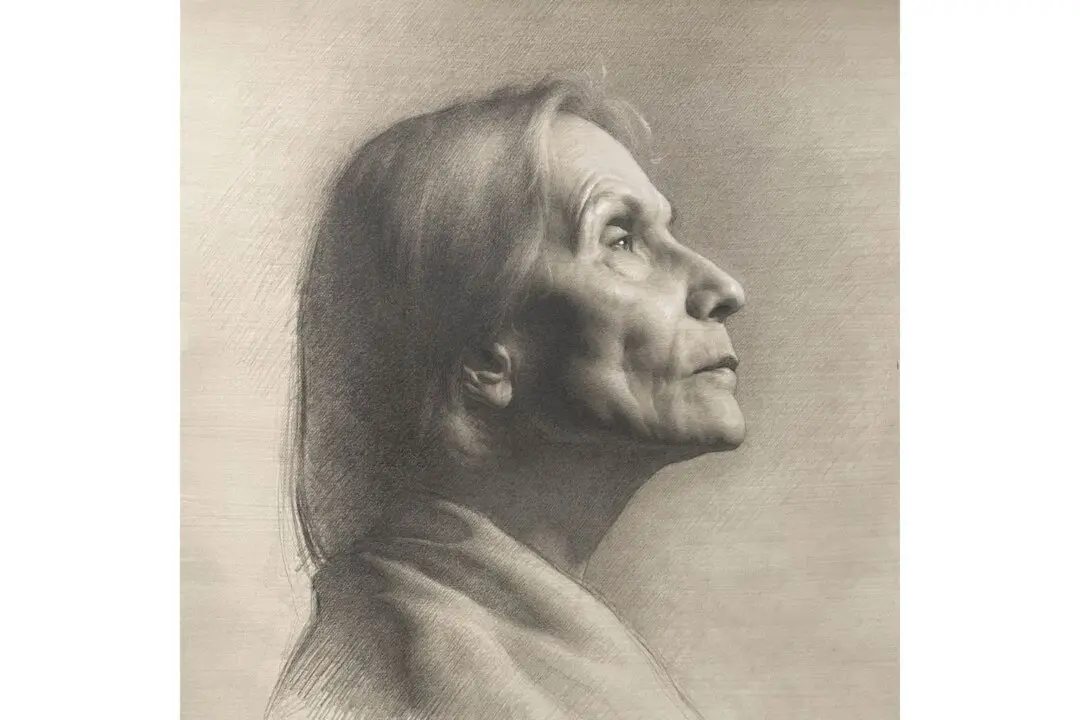

Wedgwood came from a family of well-established potters in Staffordshire, England. His father, brother, and cousins all worked in the craft. But it was Wedgwood (1730–1795) who became known as the “Father of English Potters.”