Focus

3-D printing

LATEST

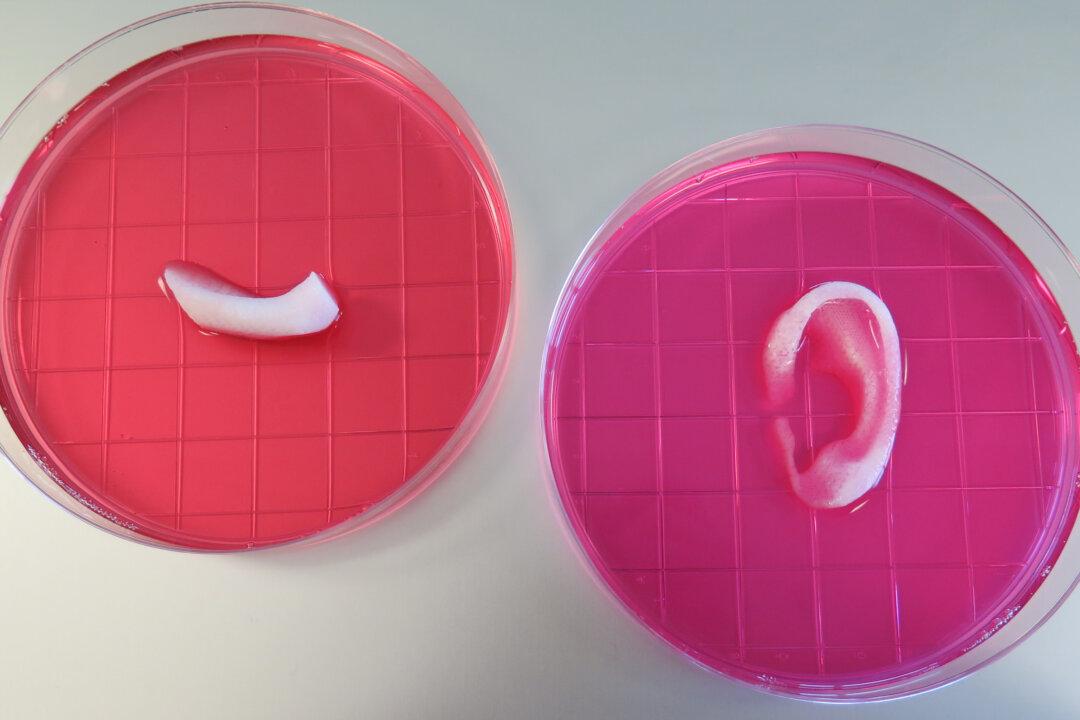

Amazing 3D Printer Can Create Ears, Jawbone, and Muscle

Biologists at Wake Forest University have successfully 3D printed living tissue structures that can function as bone and muscle replacements for humans.

|

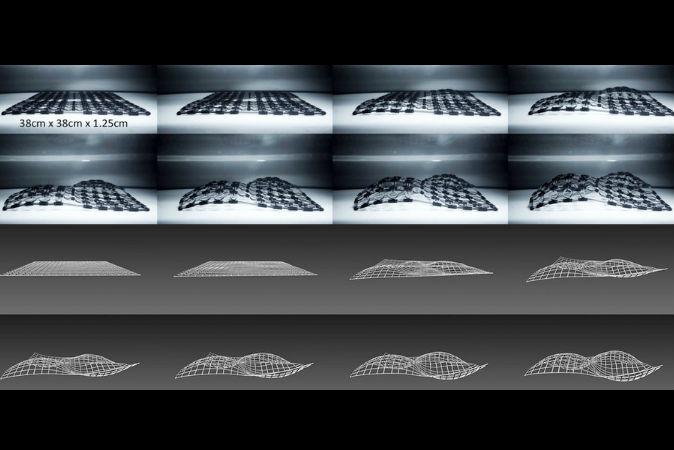

Explainer: What Is 4-D Printing?

There’s more that can be done with 3-D printed materials to make them more flexible and more useful: structures that can transform in a pre-programmed way in response to a stimulus. Recently given the popular science name of “4-D printing”, perhaps a better way to think about it is that the object transforms over time.

|

‘Starfish’ Crystals Could Lead to 3-D-Printed Pills

Engineers have figured out how to make rounded crystals with no facets, a design that mimics the hard-to-duplicate texture of starfish shells.

|

The New Family Portrait? 3D-Printed Statue Selfies

Walk into Eddie DaRoza’s office and you'll find two of him there: the actual 32-year-old video producer, and a 5-inch statuette of him.

|

Beyond the Hype: The Industrial Challenges for 3-D Printing

Apart from very high level machines, costing several million dollars each, 3-D printing tends to produce items that are less ‘resistant’ than classic moulded parts. Layer by layer build-up leads to a structural weakness in the 3rd (vertical) dimension This material drawback affects state-of-the-art processes such as selective laser sintering using polyetherketoneketone (PTKK). The surface quality is rougher.

|

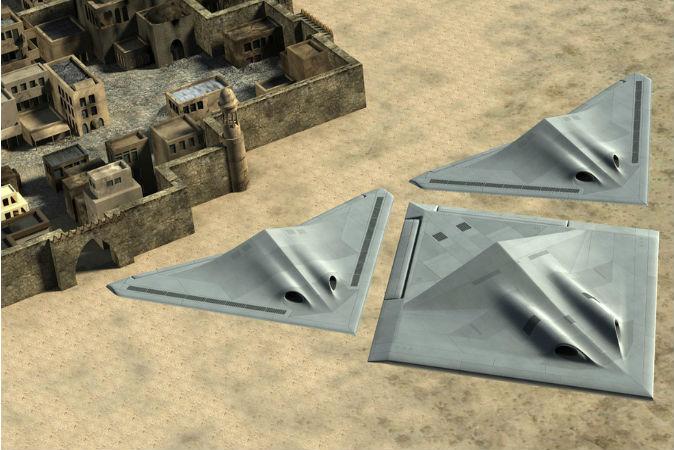

Awesome Futuristic Aircraft Designs: Can Transform, Self-Repair, More (+Videos)

UK defense and aerospace company BAE Systems is looking at developing military aircraft that seem to fly right out of a science-fiction movie.

|

Inventor of 3-D Printing Talks Beginnings, Future, and—Most Important—Present

Although Charles “Chuck” Hull, the inventor of 3-D printing, would not call himself a futurist. His invention started as a way to build prototypes, and he sees that as one of its most useful applications to this day. He focuses on the present.

|

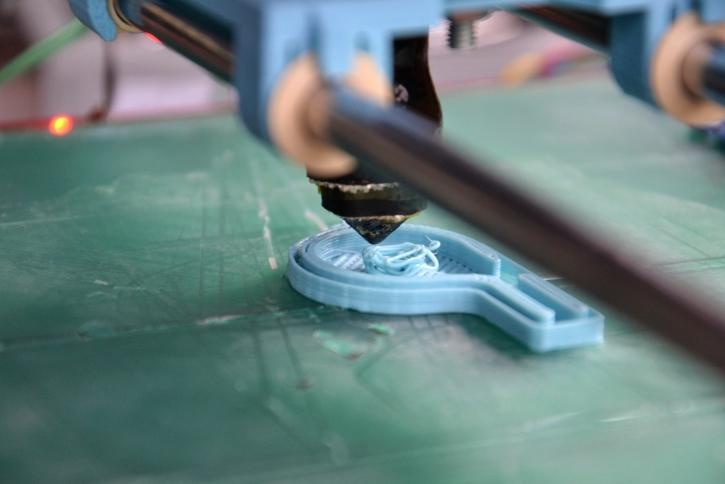

3-D Printing Gives 11-Year-Old Boy a New Hand

3-D printing gave a little boy in Buenos Aires a prosthetic hand, a designing challenge for 3-D specialists.

|

7 Headlines You Won’t Read Anywhere Else Today: March 29

A look at our world through local headlines on March 29, 2014: “Barcelona gets Europe’s first ‘3D printer café,’” “Beer glass basics,” “Africa Builds the World’s Largest Radio Telescope,” and more.

|

Amazing 3D Printer Can Create Ears, Jawbone, and Muscle

Biologists at Wake Forest University have successfully 3D printed living tissue structures that can function as bone and muscle replacements for humans.

|

Explainer: What Is 4-D Printing?

There’s more that can be done with 3-D printed materials to make them more flexible and more useful: structures that can transform in a pre-programmed way in response to a stimulus. Recently given the popular science name of “4-D printing”, perhaps a better way to think about it is that the object transforms over time.

|

‘Starfish’ Crystals Could Lead to 3-D-Printed Pills

Engineers have figured out how to make rounded crystals with no facets, a design that mimics the hard-to-duplicate texture of starfish shells.

|

The New Family Portrait? 3D-Printed Statue Selfies

Walk into Eddie DaRoza’s office and you'll find two of him there: the actual 32-year-old video producer, and a 5-inch statuette of him.

|

Beyond the Hype: The Industrial Challenges for 3-D Printing

Apart from very high level machines, costing several million dollars each, 3-D printing tends to produce items that are less ‘resistant’ than classic moulded parts. Layer by layer build-up leads to a structural weakness in the 3rd (vertical) dimension This material drawback affects state-of-the-art processes such as selective laser sintering using polyetherketoneketone (PTKK). The surface quality is rougher.

|

Awesome Futuristic Aircraft Designs: Can Transform, Self-Repair, More (+Videos)

UK defense and aerospace company BAE Systems is looking at developing military aircraft that seem to fly right out of a science-fiction movie.

|

Inventor of 3-D Printing Talks Beginnings, Future, and—Most Important—Present

Although Charles “Chuck” Hull, the inventor of 3-D printing, would not call himself a futurist. His invention started as a way to build prototypes, and he sees that as one of its most useful applications to this day. He focuses on the present.

|

3-D Printing Gives 11-Year-Old Boy a New Hand

3-D printing gave a little boy in Buenos Aires a prosthetic hand, a designing challenge for 3-D specialists.

|

7 Headlines You Won’t Read Anywhere Else Today: March 29

A look at our world through local headlines on March 29, 2014: “Barcelona gets Europe’s first ‘3D printer café,’” “Beer glass basics,” “Africa Builds the World’s Largest Radio Telescope,” and more.

|