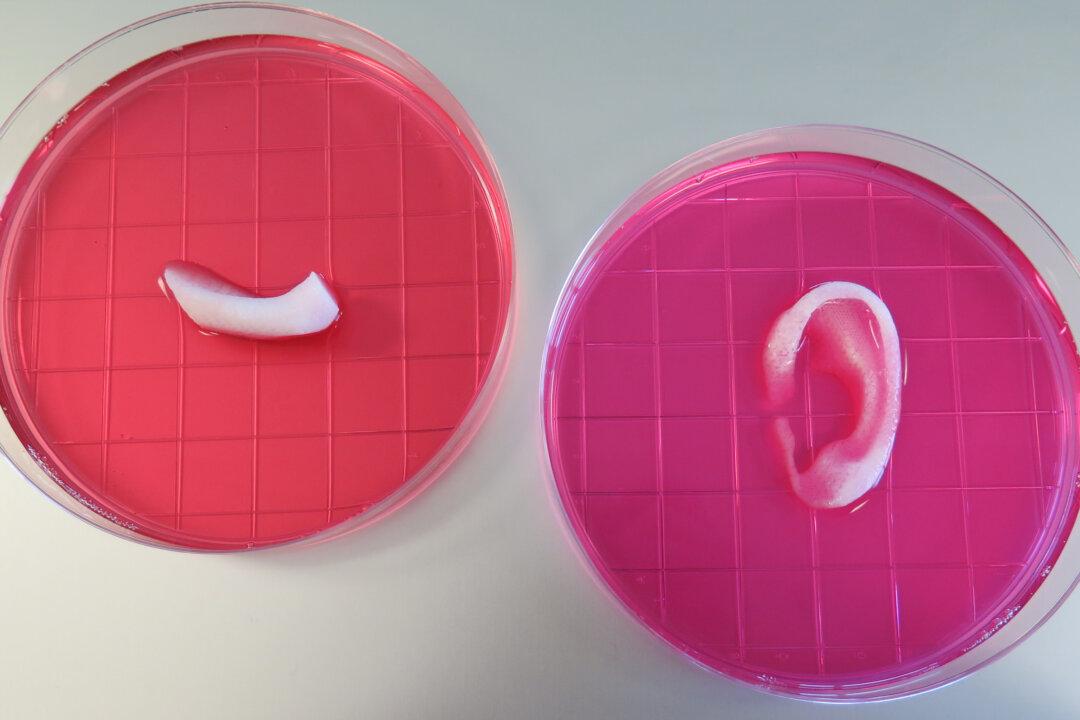

Biologists at Wake Forest University have successfully 3-D printed living tissue structures that can function as bone and muscle replacements for humans.

A custom 3-D printer created ear, bone, and muscle structures that, when implanted into animals, matured into functional tissue and developed a system of blood vessels.

This novel tissue and organ printer is an important advance in our quest to make replacement tissue for patients.

, director, Wake Forest Institute for Regenerative Medicine