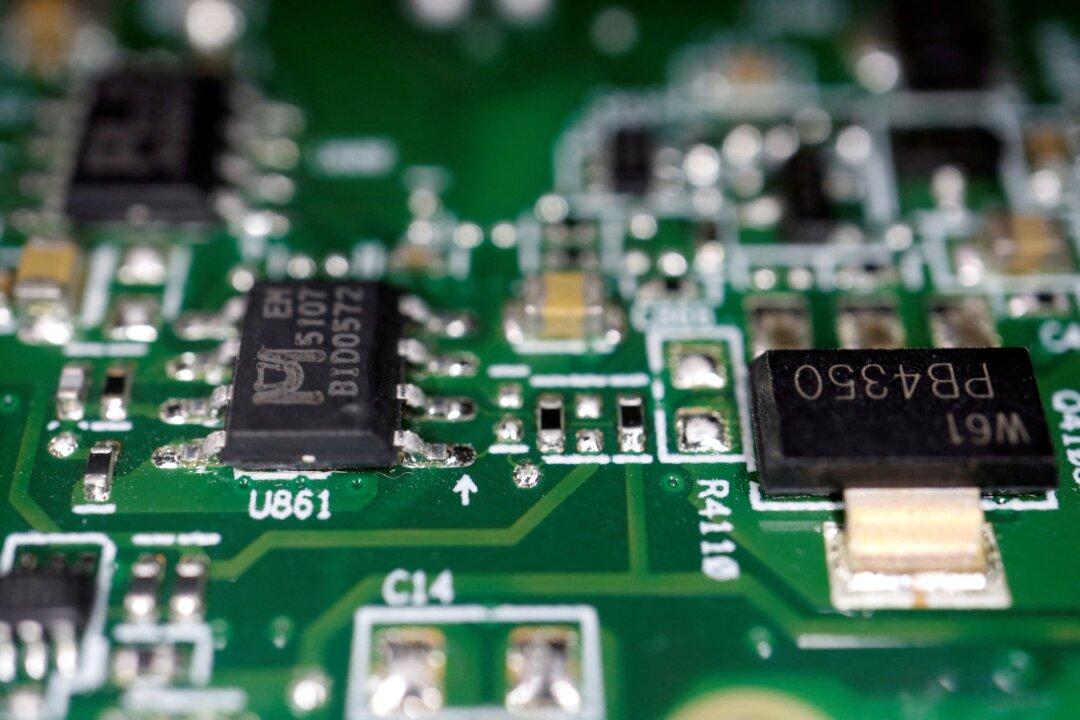

Upstate New York will be home to a national hub for cutting-edge semiconductor research, unlocking $825 million in federal funding to grow the United States’ domestic supply of computer chips.

Sen. Chuck Schumer (D-N.Y.) announced Thursday that the Albany NanoTech campus has been selected to host the national headquarters for research into extreme ultraviolet (EUV) lithography, a sophisticated technology essential to make high-end chips that power smartphones, laptops, and computer servers.