South Carolina has joined the growing list of states that are incentivizing the production of electric vehicles and their batteries.

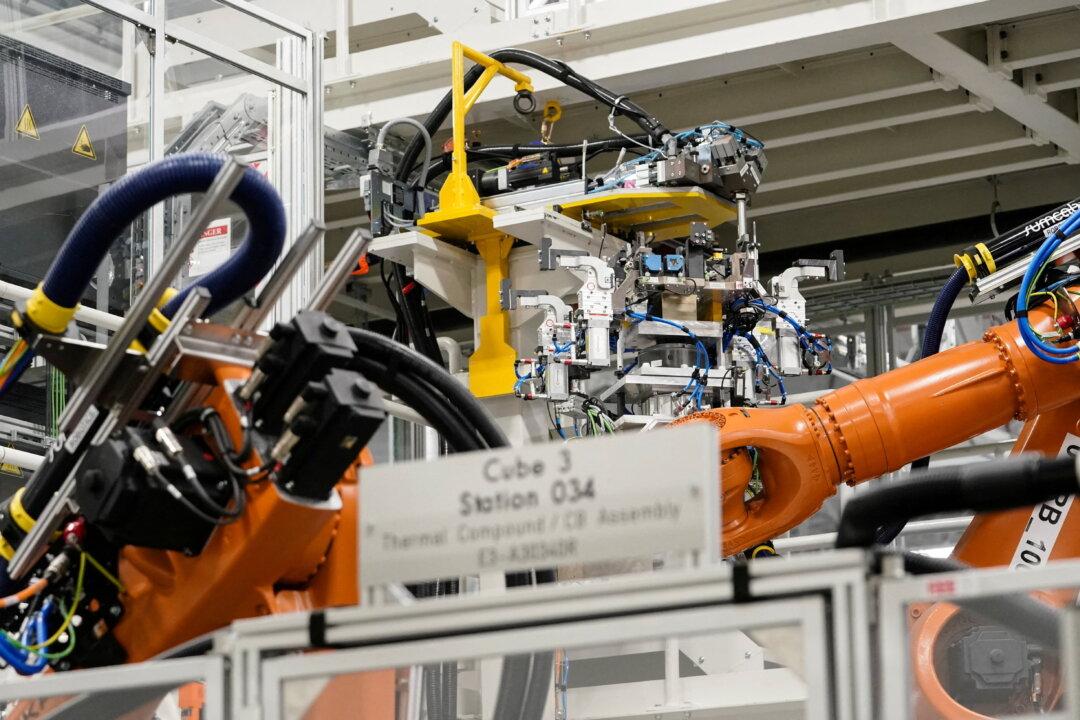

On Dec. 6, Republican Gov. Henry McMaster and Envision Automotive Energy Supply Company—a Japanese electric vehicle battery technology company—announced an $810 million investment in Florence County to build a battery cell plant that McMaster said will create 1,170 jobs while fulfilling a multi-year partnership with the BMW Group.