An Australian construction company has partnered up with the University of New South Wales (UNSW) to fast-track the development of a 3D printer to build lunar dwellings.

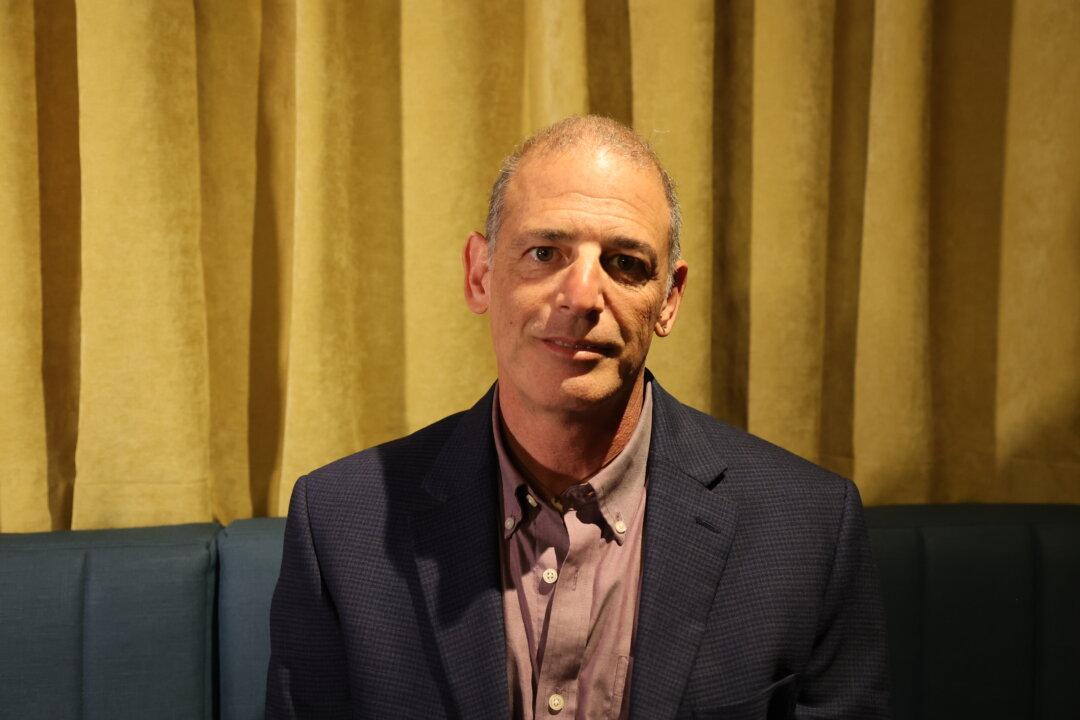

Luyten co-founder and CEO, Ahmed Mahil, said he was over the moon about the collaboration.