Today, we’re surrounded by a variety of electronic devices that are moving increasingly closer to us – we can attach and wear them, or even implant electronics inside our bodies.

Many types of smart devices are readily available and convenient to use. The goal now is to make wearable electronics that are flexible, sustainable and powered by ambient renewable energy.

This last goal inspired a group of Korea Advanced Institute of Science and Technology (KAIST) researchers to explore how the attractive physical features of zinc oxide (ZnO) materials could be more effectively used to tap into abundant mechanical energy sources to power micro devices. They discovered that inserting aluminum nitride insulating layers into ZnO-based energy harvesting devices led to a significant improvement of the devices’ performance. The researchers report their findings in the journal Applied Physics Letters, from AIP Publishing.

“Mechanical energy exists everywhere, all the time, and in a variety of forms – including movement, sound and vibration. The conversion from mechanical energy to electrical energy is a reliable approach to obtain electricity for powering the sustainable, wireless and flexible devices – free of environmental limitations,” explained Giwan Yoon, a professor in the Department of Electrical Engineering at KAIST.

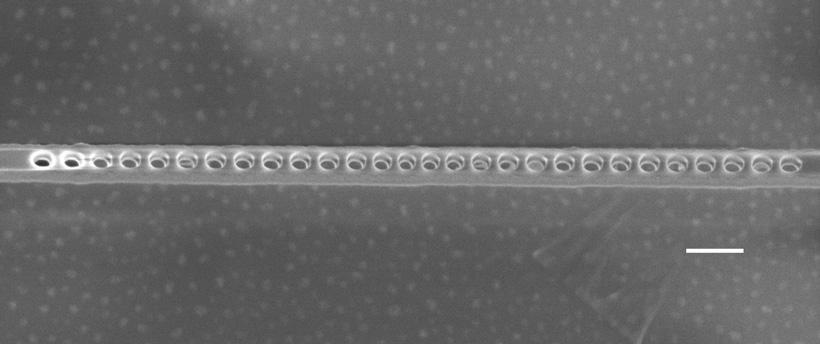

Piezoelectric materials such as ZnO, as well as several others, have the ability to convert mechanical energy to electrical energy, and vice versa. “ZnO nanostructures are particularly suitable as nanogenerator functional elements, thanks to their numerous virtues including transparency, lead-free biocompatibility, nanostructural formability, chemical stability, and coupled piezoelectric and semiconductor properties,” noted Yoon.

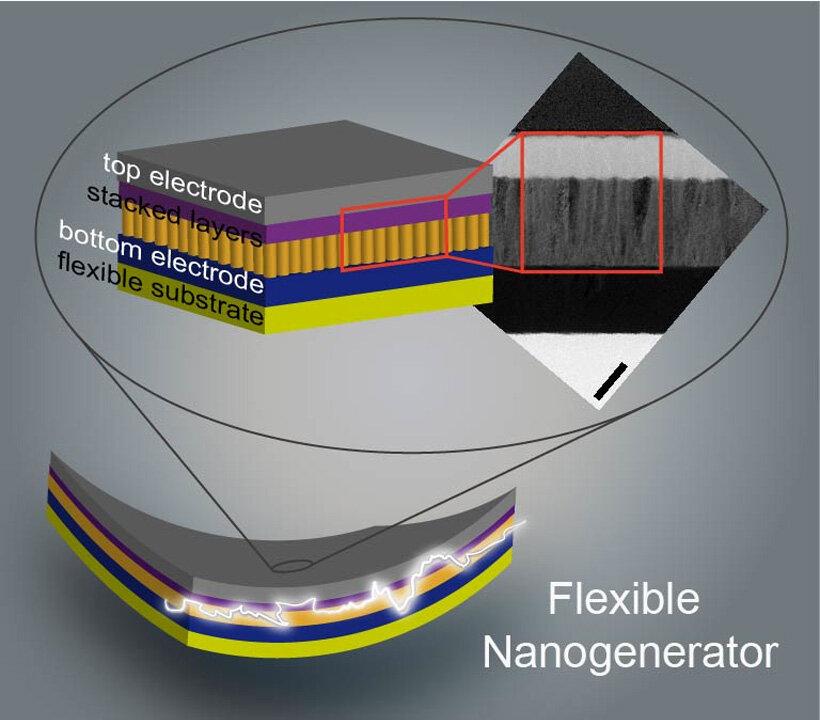

The key concept behind the group’s work? Flexible ZnO-based micro energy harvesting devices, aka “nanogenerators,” can essentially be comprised of piezoelectric ZnO nanorod or nanowire arrays sandwiched between two electrodes formed on the flexible substrates. In brief, the working mechanisms involved can be explained as a transient flow of electrons driven by the piezoelectric potential.

“When flexible devices can be easily mechanically deformed by various external excitations, strained ZnO nanorods or nanowires tend to generate polarized charges, which, in turn, generate piezoelectronic fields,” said Yoon. “This allows charges to accumulate on electrodes and it generates an external current flow, which leads to electronic signals. Either we can use the electrical output signals directly or store them in energy storage devices.”

Other researchers have reported that the use of insulating materials can help provide an extremely large potential barrier. “This makes it critically important that insulating materials are carefully selected and designed – taking both the material properties and the device operation mechanism into consideration,” said Eunju Lee, a postdoctoral researcher in Yoon’s group.

To date, however, there have been few efforts made to develop new insulating materials and assess their applicability to nanogenerator devices or determine their effects on the device output performance.

The KAIST researchers proposed, for the first time, new piezoelectric ZnO/aluminum nitride (AlN) stacked layers for use in nanogenerators.

“We discovered that inserting AlN insulating layers into ZnO-based harvesting devices led to a significant improvement of their performance – regardless of the layer thickness and/or layer position in the devices,” said Lee. “Also, the output voltage performance and polarity seem to depend on the relative position and thickness of the stacked ZnO and AlN layers, but this needs to be explored further.”

The group’s findings are expected to provide an effective approach for realizing highly energy-efficient ZnO-based micro energy harvesting devices. “This is particularly useful for self-powered electronic systems that require both ubiquity and sustainability – portable communication devices, healthcare monitoring devices, environmental monitoring devices and implantable medical devices,” pointed out Yoon. And there are potentially many other applications.

The original article can be found here.