The advent of 3D printers supposedly means we can manufacture anything in our homes. But in reality most existing home 3D printers can only make things out of certain plastics, although there are industrial systems that can print certain metals.

What has so far been out of reach is a way to 3D print high-tech composite materials such as the carbon fiber composites that are used to build lightweight but extremely strong versions of things including tennis rackets, aerodynamic bikes and even aircraft parts. But researchers from my lab at Bristol University have now developed a way to transform existing 3D printers so they can also print composite materials.

When designed properly, composites have just about the best strength for their weight of any common material, making them perfect for applications that need to be very strong but light, such as aeroplanes. Composites are usually made from very long glass or carbon fibers set in a plastic matrix. It’s the presence of the fibers, and the fact that they are all carefully arranged, that makes these materials so impressively strong yet lightweight.

Simple Solution

At present, composite products are made by forming the fibers into sheets that look a bit like stiff cloth. These are then cut to shape and assembled by hand, layer-by-layer, to create the final product. As a result, composites are expensive and not easily replicated with 3D printers.

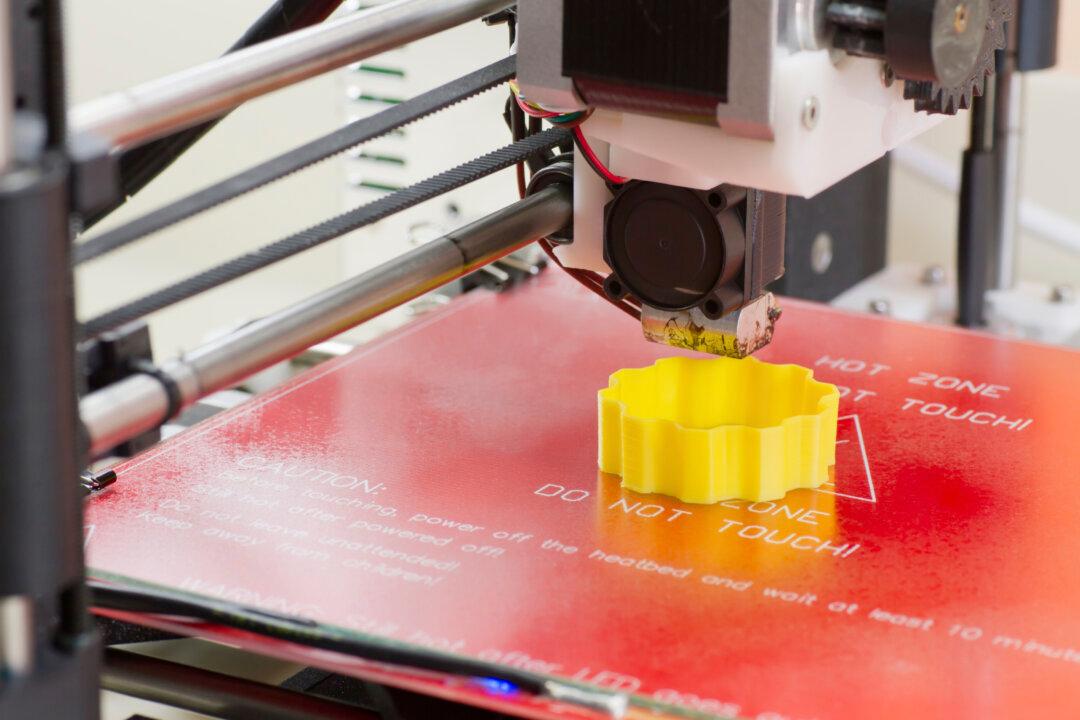

However, my colleagues and I have found a way to print composite material by making a relatively simple addition to a cheap, off-the-shelf 3D printer. The breakthrough was based on the simple idea of printing using a liquid polymer mixed with millions of tiny fibers. This makes a readily printable material that can, for example, be pushed through a tiny nozzle into the desired location. The final object can then be printed layer by layer, as with many other 3D printing processes.