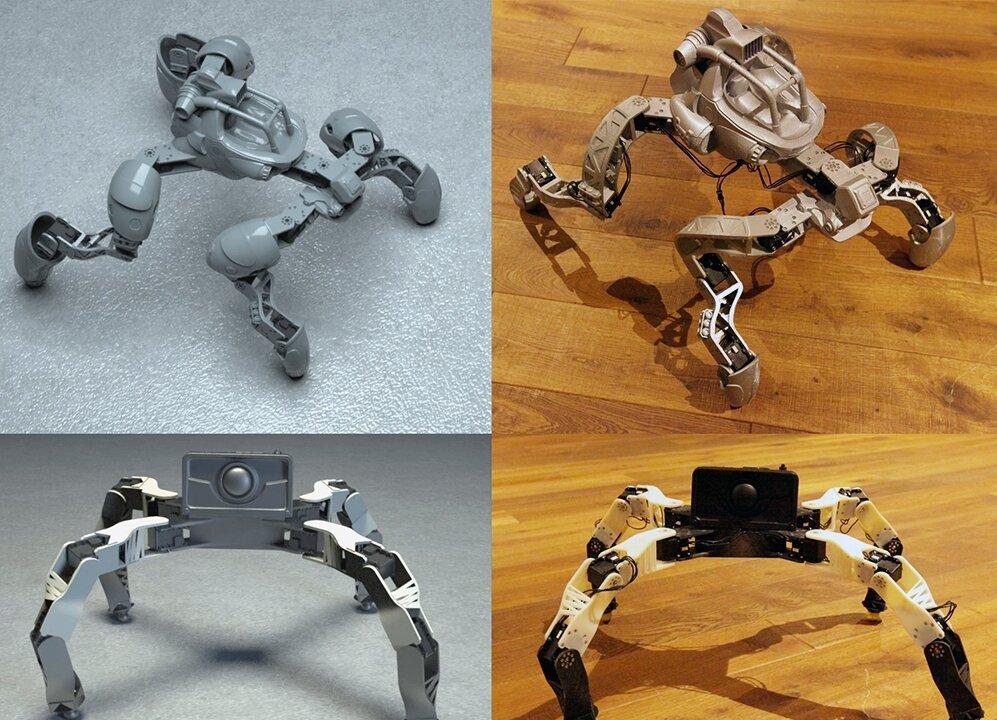

A new tool makes it possible for people—even novices—to design and build a customized walking robot using a 3D printer and off-the-shelf servo motors.

The user can specify the shape, size, and number of legs for the robotic creature, using intuitive editing tools to interactively explore design alternatives.

The system also ensures that the resulting design is capable of moving as desired and not falling down—it even lets the user alter the creature’s gait.

“Progress in rapid manufacturing technology is making it easier and easier to build customized robots, but designing a functioning robot remains a difficult challenge that requires an experienced engineer,” says Markus Gross, vice president of research for Disney Research.

“Our new design system can bridge this gap and should be of great interest to technology enthusiasts and the maker community at large.”

“We aim to reinvent the way in which personal robotic devices are designed, fabricated, and customized according to the individual needs and preferences of their users,” says Stelian Coros, a former Disney research scientist who is now an assistant professor of robotics at Carnegie Mellon University.

The research team presented the system at SIGGRAPH Asia 2015, the ACM Conference on Computer Graphics and Interactive Techniques, in Kobe, Japan.

“Our ambition is to make the design of compelling robotic creatures as accessible and intuitive as possible,” says Bernhard Thomaszewski, a research scientist at Disney Research. “Our tool allows the user to design the structure and motion of a robot while receiving immediate feedback on its expected real-world behavior.”

The design interface features two viewports: one that enables editing of the robot’s structure and motion and a second that displays how those changes would likely alter the robot’s behavior.

The user can load an initial, skeletal description of the robot and the system creates an initial geometry and places a motor at each joint position. The user can then edit the robot’s structure, adding or removing motors, or adjusting their position and orientation.

The system takes over much of the non-intuitive and tedious task of planning the motion of the robot. The user nonetheless is able to adjust the robot’s footfall pattern and stylistic elements of its motion.