When Thomas Edison wanted a filament for his light bulb, he scoured the globe collecting thousands of candidates before settling on bamboo. (It was years before people were able to make tungsten work properly.) That’s our traditional way of getting materials. We picked up stones for axes, chopped wood for housing, and carved tools out of bone.

Then we learned to synthesize new materials out of old ones, like shaping clay into bricks or pots and baking them into stone. Plastics entered our repertoire as a concoction of cotton, acid, and wood tar.

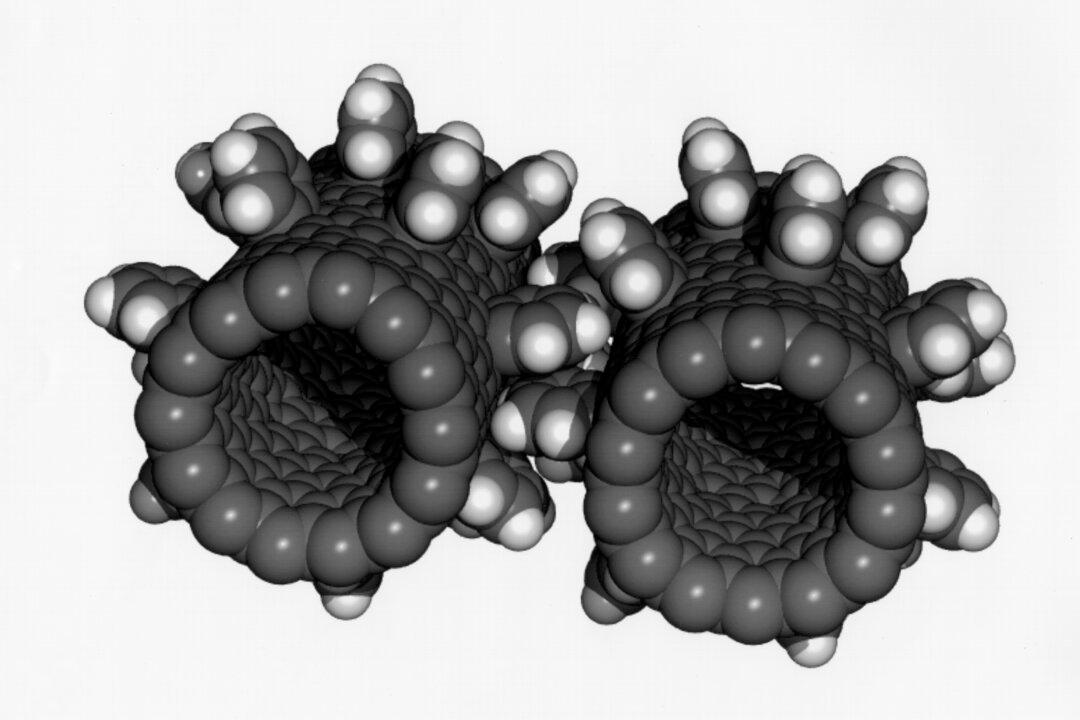

A very early materials scientist: Albertus Magnus. Sailko, CC BY-SA