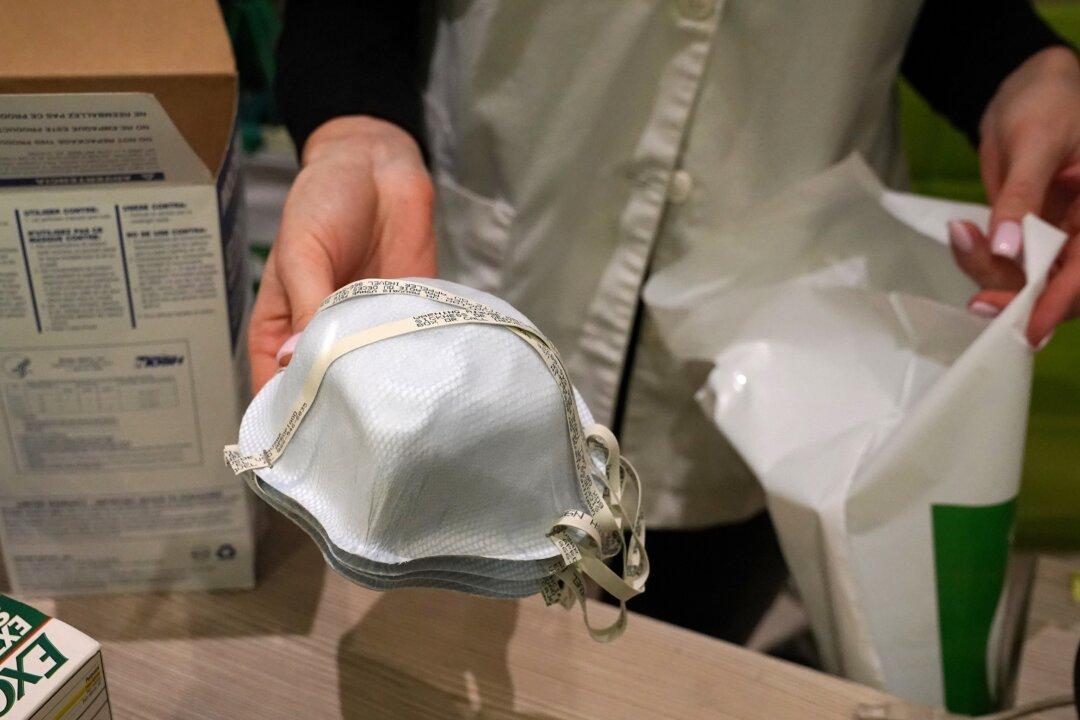

A mask sterilizing system developed by an Ohio-based company has been approved by the Food and Drug Administration amid fears of shortages of N95 respirators, masks used by healthcare workers caring for COVID-19 patients.

The mask sterilizing system was developed by Battelle. After 2 1/2 hours of exposure to concentrated, vapor phase hydrogen peroxide, the used masks are decontaminated, the company said in a statement. Each system can decontaminate up to 80,000 masks when running at full capacity.