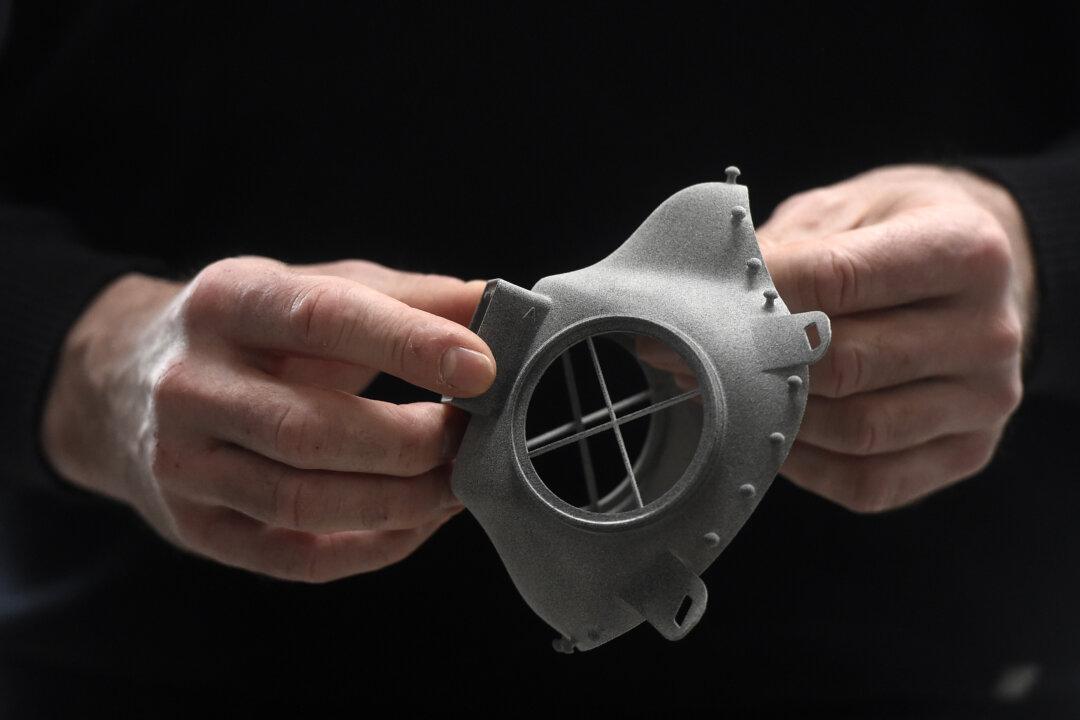

Health officials said federal agencies are working to spur regulatory and scientific innovation around 3D printing in the fight against the COVID-19 pandemic.

The Food and Drug Administration (FDA) said on March 26 that it entered into a Memorandum of Understanding (MOU) with agencies including the Department of Veterans Affairs and the National Institutes of Health and the National Institute of Allergy and Infectious Diseases.